A manual transmission shift linkage diagram is a visual guide illustrating the components and connections within a vehicle’s manual shift system, aiding drivers and technicians in understanding gear engagement and diagnosing issues efficiently.

1.1 Definition and Purpose

A manual transmission shift linkage diagram is a detailed visual representation of the components and connections within a vehicle’s manual shift system; Its primary purpose is to illustrate how gears are engaged and disengaged, aiding drivers and technicians in understanding the mechanism, diagnosing issues, and guiding repairs or adjustments effectively.

1.2 Importance of Understanding the Shift Linkage System

Understanding the shift linkage system is crucial for diagnosing and resolving shifting issues, such as gear misalignment or worn components. Proper knowledge ensures smooth gear transitions, prevents transmission damage, and enhances driving performance, making it essential for both maintenance and troubleshooting in manual transmissions.

Key Components of the Manual Transmission Shift Linkage

The manual transmission shift linkage includes essential components like the shift assembly, shift rods, shift forks, and synchronizers, which work together to facilitate precise gear engagement and smooth shifting operation.

2.1 Shift Assembly and External Linkage

The shift assembly includes the gearshift lever and external linkage, connecting the driver’s input to the transmission. It translates the driver’s movements into mechanical signals, engaging the appropriate gears. The external linkage comprises rods and couplers, ensuring precise communication between the shift lever and the transmission’s internal mechanisms, enabling smooth and accurate gear transitions.

2.2 Internal Shift Cam and Shift Arm Components

The internal shift cam and shift arm components are critical within the transmission. The shift cam synchronizes gear shifts, while shift arms connect to shift forks, engaging gears. These components work in harmony to ensure smooth transitions between gears, with the cam controlling the timing and the arms executing the mechanical movements precisely.

2.3 Shift Forks and Synchronizers

Shift forks and synchronizers are essential for engaging gears. The shift fork connects to the shift rail, moving the synchronizer to mesh gears. The synchronizer ensures smooth gear engagement by equalizing speed between shafts, preventing grinding. Together, they facilitate seamless transitions, making manual shifting efficient and controlled.

How the Shift Linkage System Operates

The shift linkage system operates by connecting the gearshift lever to the transmission, enabling the driver to engage gears through the movement of shift forks and synchronizers, ensuring smooth transitions.

3.1 Driver Interaction with the Gear Shift Lever

Driver interaction starts with moving the gearshift lever, which transmits mechanical signals through the shift linkage to the transmission. This movement engages specific gears by actuating internal components, ensuring the vehicle accelerates smoothly through its speed ranges. Proper driver technique is essential for efficient and precise gear changes, minimizing wear on components.

3.2 Movement of Shift Rails and Forks

When the driver moves the gearshift lever, it activates the shift rail, which slides along the transmission. This motion moves the shift fork, engaging or disengaging gears by aligning with synchronizers. The precise movement ensures smooth gear transitions, with synchronization minimizing wear and ensuring proper mechanical engagement during shifts. Alignment is critical for functionality.

3.4 Engagement of Gears and Synchronizers

The shift fork, guided by the shift rail, moves the synchronizer ring to mesh with the desired gear. This ensures smooth engagement by aligning the gear teeth. The clutch disengages to prevent grinding, and once the gear is fully engaged, the clutch is released, completing the gear change. Proper timing ensures seamless transitions.

Types of Shift Linkage Diagrams

Shift linkage diagrams vary by transmission type, including Muncie 4-speed, Saginaw 4-speed, and 5/6-speed systems, each detailing unique components and their interactions for precise gear engagement.

4.1 Muncie 4-Speed Transmission Diagram

The Muncie 4-speed transmission diagram outlines the components and connections specific to this durable and popular gearbox. It includes the shifter assembly, shift rods, shift arms, and transmission casing, providing a clear visual guide for understanding gear engagement and troubleshooting common issues in classic and high-performance vehicles.

4.2 Saginaw 4-Speed Transmission Diagram

The Saginaw 4-speed transmission diagram provides a detailed illustration of its shift linkage system, showcasing how components like shift rods, forks, and synchronizers interact. This visual aid helps technicians and enthusiasts understand gear engagement processes, facilitating repairs and adjustments for smooth shifting in classic vehicles equipped with this reliable manual transmission.

4.3 5-Speed and 6-Speed Transmission Diagrams

5-speed and 6-speed transmission diagrams offer comprehensive views of modern manual shift systems, highlighting intricate components like multiple shift rails and synchronizers; These diagrams are essential for diagnosing issues in high-performance vehicles, ensuring precise gear engagement and smoother shifting capabilities compared to traditional 4-speed systems.

Troubleshooting Common Issues

Troubleshooting common issues in manual transmissions often starts with identifying symptoms like difficulty shifting or gear misalignment. Inspecting shift linkage components for wear or misalignment is crucial for resolving problems and ensuring smooth operation.

5.1 Symptoms of Worn or Misaligned Shift Linkage

Common symptoms of worn or misaligned shift linkage include difficulty engaging gears, loose or sloppy shifting, grinding noises, and delayed or unresponsive gear changes. These issues can lead to transmission damage if not promptly addressed, emphasizing the need for regular inspections and adjustments to maintain smooth operation and prevent costly repairs.

5.2 Adjustment and Repair Procedures

Adjustment and repair involve inspecting shift linkage components for wear or misalignment, tightening loose connections, and replacing damaged parts. Proper alignment ensures smooth gear transitions, while lubrication of moving parts prevents friction. Detailed diagrams guide technicians through precise adjustments, ensuring optimal performance and extending the lifespan of the manual transmission system.

5.3 Checking for Excessive Play in Components

Excessive play in shift linkage components, such as shift rods or forks, can cause poor shifting. Inspect for worn bushings, loose connections, or damaged pins. Use diagrams to locate components and measure play with precision tools. Correcting excessive play ensures accurate gear engagement and smooth manual transmission operation, preventing further mechanical damage.

Maintenance and Adjustment of Shift Linkage

Regular cleaning and lubrication of shift components ensure smooth operation. Tightening shift rod locknuts and reconnecting rods maintain proper alignment, preventing excessive play and improving gear engagement accuracy.

6.1 Cleaning and Lubricating Shift Components

Regular cleaning of shift components with a solvent prevents dirt buildup. Applying grease to pivot points and joints ensures smooth operation. Lubrication reduces friction, preventing wear and tear. Proper maintenance enhances shifting precision and longevity of the linkage system, ensuring reliable gear engagement and overall transmission performance.

6.2 Tightening Shift Rod Locknuts

Tightening shift rod locknuts ensures secure connections between components. Proper torque specifications prevent excessive play or slippage. Over-tightening can damage threads, so careful adjustment is crucial. Secure locknuts enhance system stability, maintaining precise gear shifts and overall transmission reliability over time.

6.3 Reconnecting Shift Rods and Lever

Reconnecting shift rods and the lever ensures proper alignment and functionality. Use calibrated tools to secure connections without over-tightening, which can damage threads. Proper alignment ensures smooth gear transitions, preventing misalignment issues. This step is critical for maintaining precise control over the transmission system and ensuring reliable performance during driving.

Visual Representation and Diagrams

Visual representations provide a clear understanding of the shift linkage system, illustrating component locations and interactions. Diagrams are essential for troubleshooting, repairs, and ensuring proper system functionality and alignment.

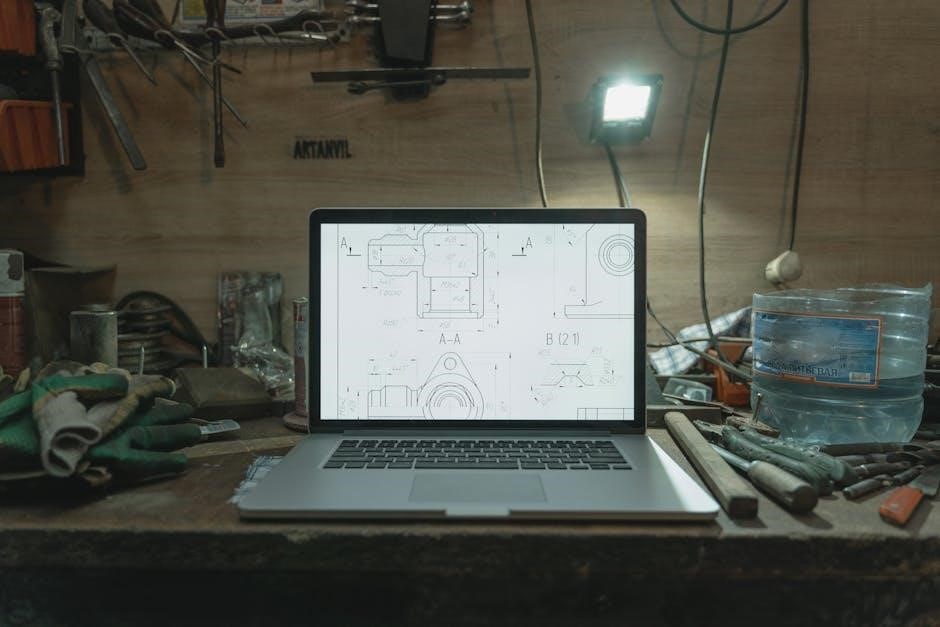

7.1 Detailed Shift Linkage Schematics

Detailed shift linkage schematics provide a comprehensive view of the system, showcasing the interconnections between shift rails, forks, and synchronizers. These diagrams highlight precise component locations and interactions, aiding technicians in troubleshooting and repairs. They often include labels for gears, levers, and rods, ensuring clarity in understanding how the system operates during gear engagement and alignment.

7.2 Component Locations and Interactions

Component locations and interactions are critical in understanding how the shift linkage operates. The shift rails, forks, and synchronizers are positioned to connect the gear shifter to the transmission. These components work in harmony to engage gears smoothly, with the shift fork moving the synchronizer to align and lock gears during shifts. Proper alignment ensures efficient operation.

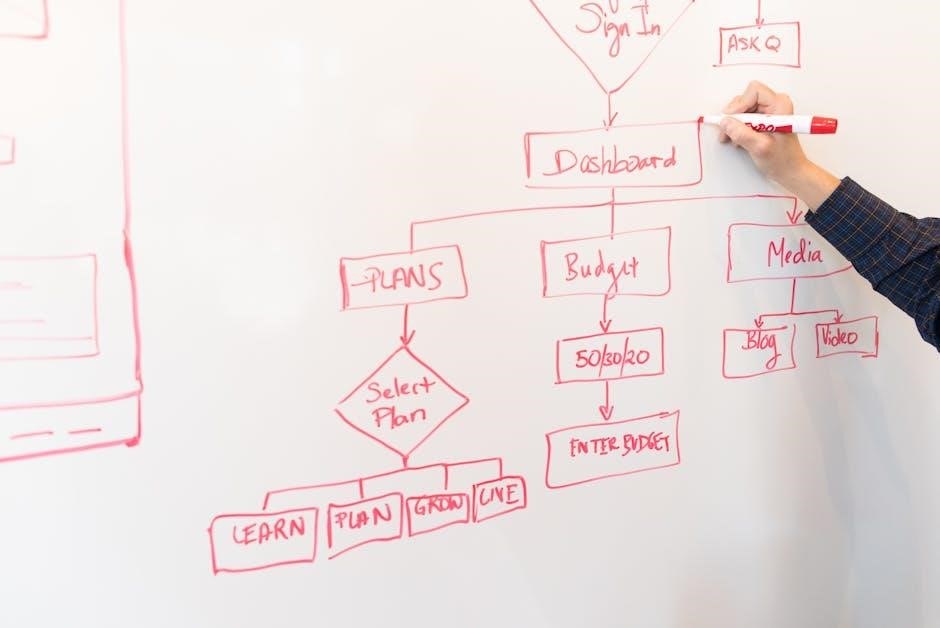

7.3 Step-by-Step Adjustment Guides

Step-by-step adjustment guides provide clear instructions for aligning and fine-tuning shift linkage components. Start by loosening locknuts, then adjust shift rod lengths to ensure proper gear engagement. Tighten locknuts securely and test shifting to confirm smooth operation. If issues persist, refer to detailed diagrams for additional guidance on realigning components accurately.

Best Practices for Working with Shift Linkage

Best practices emphasize using proper tools and following safety precautions to avoid damaging components. Regular lubrication and checking for wear ensure optimal performance and prevent unexpected failures during operation.

8.1 Tools and Materials Required

Essential tools include a torque wrench, socket set, Allen keys, and pliers. Materials needed are shift rod locknuts, bushings, and silicone-based grease. These ensure precise adjustments and prevent component wear, maintaining smooth gear shifts and system longevity.

8.2 Safety Precautions

Always wear protective gloves and eyewear when working with manual transmission components. Ensure the vehicle is securely supported on jack stands to avoid accidents. Disconnect the battery to prevent electrical hazards. Never attempt adjustments while the engine is running or in gear, and keep loose clothing tied back to avoid entanglement.

8.3 Avoiding Common Mistakes

Strictly follow adjustment procedures to prevent misalignment of shift components. Avoid over-tightening locknuts, as this can restrict smooth shifting. Ensure all bushings and bearings are properly lubricated. Never force gears into position, as this can damage synchronizers or forks. Always refer to the shift linkage diagram for accurate component locations and interactions.

Future Trends and Innovations

Advancements include electronic shift linkage systems for smoother operation and automatic adjustments. Integration with modern transmission designs enhances efficiency and precision, reducing mechanical complexities and improving driver experience.

9.1 Electronic Shift Linkage Systems

Electronic shift linkage systems integrate sensors and actuators to automate gear shifts, reducing driver effort. These systems enhance precision and speed, offering adaptive shifting based on driving conditions. They maintain the feel of manual control while improving efficiency, making them a bridge between traditional manuals and automatic transmissions.

9.2 Automatic Adjustments and Sensors

Modern manual transmissions incorporate automatic adjustments and sensors to optimize shifting performance. These systems use real-time data from sensors to self-calibrate and ensure precise gear engagement. Sensors monitor factors like speed and driver input, enabling smoother transitions and reduced wear on components, while maintaining the traditional feel of manual shifting.

9.3 Integration with Modern Transmission Designs

Modern manual transmissions integrate advanced technologies, combining electronic controls with traditional shift linkage systems. These designs enhance efficiency and performance while maintaining driver engagement. Lightweight materials and optimized gear ratios improve fuel economy and responsiveness. The integration of sensors and electronic aids ensures smoother operation without compromising the manual shifting experience.

Understanding the manual transmission shift linkage diagram is essential for drivers and technicians, offering insights into gear engagement and system maintenance. Regular upkeep ensures smooth operation and longevity of components.

10.1 Summary of Key Points

A manual transmission shift linkage diagram provides a clear overview of the system, highlighting components like shift rails, forks, and synchronizers. Proper understanding and maintenance ensure smooth gear transitions, reduce wear, and prevent common issues. Regular adjustments and inspections are crucial for optimal performance and longevity of the transmission system.

10.2 Final Tips for DIY Enthusiasts

- Always consult a shift linkage diagram for your specific transmission to ensure accurate adjustments.

- Use specialized tools to avoid damaging components during repairs or adjustments.

- Work in a well-lit, secure environment to maintain visibility and safety.

- Test the system thoroughly after adjustments to ensure smooth gear engagement.